Refractory High Alumina Castable

Price 13500 INR/ Ton

Refractory High Alumina Castable Specification

- Application

- STEEL PLANT , ROLLING MILL

- Product Type

- Mineral Refractories

- Dimensional Stability

- Other

- Strength

- 650

- Specific Gravity

- 2.7

- Chemical Composition

- AL2O3 = 90% , FE2O3 = 1%

- Color

- WHITE

Refractory High Alumina Castable Trade Information

- Minimum Order Quantity

- 1 Ton

- FOB Port

- TA-KADI

- Supply Ability

- 1 Ton Per Day

- Delivery Time

- 1 Days

- Sample Available

- Yes

- Sample Policy

- Free samples available with shipping and taxes paid by the buyer

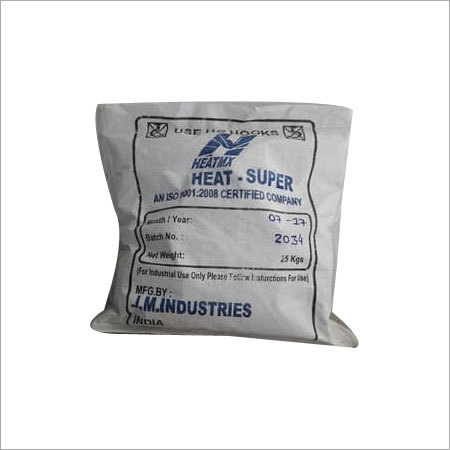

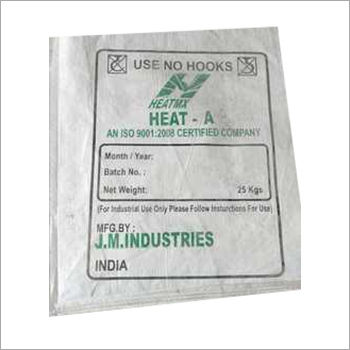

- Packaging Details

- 25 KG

- Main Domestic Market

- Gujarat

- Certifications

- ISO 9001:2008

About Refractory High Alumina Castable

It is suitable for areas that require high temperature insulation. We are glad to present ourselves as one of the leading organizations engaged in offeringRefractory High Alumina Castable. This castable is able to decrease overall density of lining as well as the cold face temperature. It is used in many industrial and energy applications including boilers, furnaces, and precast burner bricks. Also,Refractory High Alumina Castable can be used in sub-floor applications such as in brick kilns and kiln car bases.

Features:

- Compensated shrinkage

- High mechanical strength

- Resistance to aggressive agents

Product Details:

AL2O3 = 90% , FE2O3 = 1%

|

Packaging Type |

Bag |

|

Packaging Size |

25 KG |

|

Brand |

HEAT |

Superior Chemical Composition for Industrial Demands

With 90% alumina content, our high alumina castable delivers unmatched thermal stability and corrosion resistance, making it ideal for harsh working conditions in steel and rolling mill environments. The low iron oxide level (1% Fe2O3) enhances its durability, minimizing unwanted reactions and extending the lifespan of furnace linings.

Optimized for Performance and Safety

This castable sets the benchmark for strength and color consistency. The materials white finish not only reflects its purity but also aids in visual inspection during maintenance. With a strength rating of 650, it remains robust under heavy operational loads, ensuring structural integrity in high-heat zones.

FAQs of Refractory High Alumina Castable:

Q: How is Refractory High Alumina Castable applied in steel plants and rolling mills?

A: This castable is typically mixed with water to achieve the desired consistency and then cast or poured into molds or lining forms within furnaces, ladles, or rolling mill equipment. It sets and hardens to provide a protective thermal barrier that withstands high temperatures.Q: What is the benefit of having 90% AL2O3 in the castables composition?

A: A 90% alumina content ensures exceptional heat resistance, mechanical strength, and chemical stability, making it suitable for aggressive industrial environments where temperature and abrasion resistance are critical.Q: When is the best time to use this castable in your installation process?

A: It should be applied during the refractory lining or repair phase, ensuring surfaces are clean and prepared for optimal adhesion and curing. This timing ensures maximum effectiveness of the castables thermal and mechanical properties.Q: Where is this refractory castable manufactured and supplied from?

A: Our Refractory High Alumina Castable is manufactured and supplied in India, ensuring reliable sourcing and support for domestic and international customers.Q: What is the process for preparing and installing this castable?

A: The process involves mixing the castable powder with water, adhering to manufacturer-specified ratios. After mixing, the slurry is poured or troweled into place, cured at ambient temperature, and then heated gradually to full operating temperatures.Q: What are the practical uses and benefits in steel plant environments?

A: This castable is ideal for linings of furnaces, burners, and other high-temperature sections within steel plants and rolling mills, offering longevity, reduced downtime, and improved safety due to its high strength and stable performance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Refractory Castable Category

Fire Clay Cement

Price 22000 INR / Ton

Minimum Order Quantity : 1 Ton

Product Type : Mineral Refractories

Color : GREY

Chemical Composition : AL2O3 = 35 , FE2O3 = 4%

Strength : 15

High Alumina Castable

Price 20000 INR / Ton

Minimum Order Quantity : 1 Ton

Product Type : Mineral Refractories

Color : GREY

Chemical Composition : AL2O3= 70% , FE2O3 = 3.00 4.00 %

Strength : 300

High Alumina Refractory Castable

Price 13500-22000 INR / Ton

Minimum Order Quantity : 1 Ton

Product Type : Mineral Refractories

Color : WHITE

Chemical Composition : 60% AL2O3 , 1.50% FE2O3

Strength : 350 KG/CM

Refractory Insulating Castable

Price 20000 INR / Ton

Minimum Order Quantity : 1 Ton

Product Type : Mineral Refractories

Color : WHITE

Chemical Composition : AL2O3 = 45 , FE2O3 = 1.50%

Strength : 45

|

JAY MATRI MA INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry