Fire Clay Cement

Price 22000 INR/ Ton

Fire Clay Cement Specification

- Application

- TURNENAL KILAN , TILES PLANT AND BOILER SECTOR

- Product Type

- Mineral Refractories

- Types of Refractories

- Monolithic Refractory

- Shape

- Powder

- Strength

- 15

- Specific Gravity

- 1

- Chemical Composition

- AL2O3 = 35 , FE2O3 = 4%

- Color

- GREY

Fire Clay Cement Trade Information

- Minimum Order Quantity

- 1 Ton

- FOB Port

- TA-KADI

- Supply Ability

- 1 Ton Per Day

- Delivery Time

- 1 Days

- Sample Available

- Yes

- Sample Policy

- Free samples available with shipping and taxes paid by the buyer

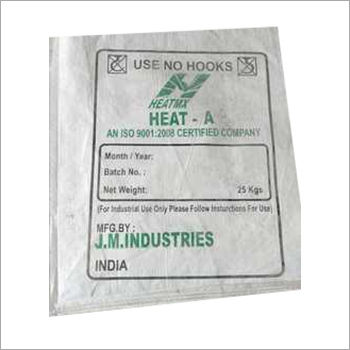

- Packaging Details

- 25 KG

- Main Domestic Market

- Gujarat

- Certifications

- ISO 9001:2008

About Fire Clay Cement

We have earned our name as a renowned manufacturer and supplier of Insulite - 11 Castable. This castable comprises of aggregates, matrix components, bonding agents, and admixtures. It can be easily blended with water, shaped and hardened like concrete. Offered castable is mainly used for making solid linings inside of a high temperature heater and furnace. It can also be used to form strong joints and applied as building construction material. Insulite -11 Castable is free from any kind of contamination with foreign materials.

Features:

- Compensated shrinkage

- High mechanical strength

- Resistance to aggressive agents

Product Details:

AL2O3 = 35 , FE2O3 = 4%

|

Packaging Type |

Bag |

|

Packaging Size |

25 KG |

|

Brand |

HEAT |

Superior Performance in High-Temperature Settings

Fire Clay Cement is engineered to perform under extreme heat, making it ideal for industries such as tile manufacturing, boiler systems, and tunnel kilns. Its balanced chemical composition ensures robust bonding and reduced risk of structural failures in thermal applications. The cements adaptability in both white and grey variants meets various project requirements, offering aesthetics as well as technical efficiency.

Trusted Indian Manufacturer and Supplier

Manufactured and supplied within India, this Fire Clay Cement adheres to stringent quality standards. Clients benefit from reliable local supply, minimizing lead times and supporting rapid industrial setups. Each batch is meticulously tested to guarantee strength, consistency, and the required chemical composition, providing peace of mind for engineers and site managers.

FAQs of Fire Clay Cement:

Q: How is Fire Clay Cement used in tunnel kilns, tile plants, and boiler sectors?

A: Fire Clay Cement is commonly used for lining, insulating, and joining refractory bricks or tiles in tunnel kilns, tile plants, and boiler systems. Thanks to its high alumina (AL2O3) content and heat resistance, it effectively withstands prolonged exposure to high temperatures, thus safeguarding critical industrial equipment.Q: What is the chemical composition of this Fire Clay Cement, and why is it beneficial?

A: This cement contains 35% AL2O3 (alumina) and 4% FE2O3 (iron oxide), providing excellent heat stability, mechanical strength, and resistance to chemical attacks. These properties make it suitable for the rigorous conditions found in kilns, boilers, and tile manufacturing plants.Q: When should this Fire Clay Cement be applied during the industrial installation process?

A: Fire Clay Cement should be applied after preparing and cleaning the surfaces, just before placing or assembling refractories. It acts as a bonding agent between refractory bricks or tiles, ensuring a tight, durable seal that endures thermal stress over long operational cycles.Q: Where is this Fire Clay Cement manufactured and supplied?

A: This product is manufactured and supplied in India, serving industries locally to ensure a steady, reliable source for refractory construction and maintenance projects.Q: What are the benefits of using Fire Clay Cement over regular cement in thermal applications?

A: Fire Clay Cement offers superior thermal resistance, higher mechanical strength, and specialized chemical properties compared to regular cement. These advantages make it indispensable in high-temperature environments such as kilns and boilers, where conventional cement would fail.Q: How does the color (white or grey) of the Fire Clay Cement affect its application?

A: Both colors offer the same chemical and strength characteristics, but the choice between white and grey typically depends on aesthetic or visibility needs in installation. Functionally, there is no difference regarding performance or thermal resistance.Q: What is the process for mixing and applying Fire Clay Cement?

A: To use Fire Clay Cement, mix it with the recommended amount of water to form a smooth paste. Apply this mixture evenly on clean surfaces of refractory bricks or tiles, join them firmly, and allow adequate drying or curing time before subjecting to high temperatures for optimal bonding.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Refractory Castable Category

Refractory High Alumina Castable

Price 13500 INR / Ton

Minimum Order Quantity : 1 Ton

Specific Gravity : 2.7

Application : STEEL PLANT , ROLLING MILL

Chemical Composition : AL2O3 = 90% , FE2O3 = 1%

Color : WHITE

High Quality Refractory Castable

Price 20000 INR / Ton

Minimum Order Quantity : 1 Ton

Specific Gravity : 2.5

Application : STEEL PLAN , ROLLING MILL , BOILER STRUCTURE AND CEMENT PLANT

Chemical Composition : AL2O3= 70% , FE2O3 = 3.00 4.00 %

Color : GREY

High Alumina Refractory Castable

Price 13500-22000 INR / Ton

Minimum Order Quantity : 1 Ton

Specific Gravity : 2.2

Application : STEEL PLANT , ROLLING MILL AND BOILERS

Chemical Composition : 60% AL2O3 , 1.50% FE2O3

Color : WHITE

Refractory Castable

Price 20000 INR / Ton

Minimum Order Quantity : 1 Ton

Specific Gravity : 1.50

Application : TURNAL KILAN , STEEL PLANT

Chemical Composition : AL2O3 = 48% , FE2O3 = 1.00%

Color : WHITE

|

JAY MATRI MA INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry